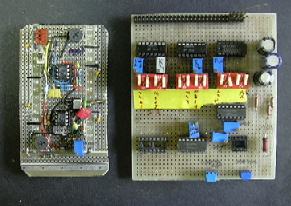

Breadboarding high power circuits that rely on the component densities of SMT for integration, where small and large signals are combined on the same assembly, can be tricky. This is particularly true if the circuits depend on multilayer printed wiring and magnetic windings to achieve this density.

The power switch section of this amplifier may be pushing the limits of the breadboarding concept, without releasing artwork to a vendor. The intended four layers are easily developed and modified in discrete single-sheet iterations, providing that interlayer connections can be reliably maintained.

A minimum of manufacturing

steps is possible if the SMD portion of mixed-technology assemblies

can be wave-soldered. The single wave operation then serves for both through-hole

and SMT parts.

Control functions, in the early stages, are best duplicated in discrete clockwork in order to study static effects over the compliance range. This also allows the early evaluation of thermal and other stress issues before mechanical packaging is finalized and tooling budgets are tapped. When CPLD firmware achieves safe-to-run characteristics, it's bugs are easily recognizable.

.

.

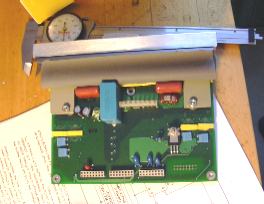

The first printed wiring purchase and metal hardware can then be introduced iteratively to the prototype, allowing for minor revisions in CPLD firmware, controller program state-machine and control/communications software, without major physical surprises.

.

.

.

.