If you've ever played around with thermionic valves, or vacuum tubes (as they are refered to in North America), you've probably noticed that they get pretty warm in operation. Although they appear fragile, with their finely drawn heater and screen wires, in their glass envelopes, they are in many ways actually quite rugged, when compared to the solid-state equivalents.

The requirement to maintain a vacuum within the envelope, combined with the temperatures that are needed to enhance thermionic emission in the cathode, are the main features acting to restrict operating life. Envelope temperature has proven to be the most detrimental of all the variables determining the reliability of electron tubes, since this data has been collected (ref 01). Elevated temperatures result in an increase in glass electrolysis (refs 01, 02).

The electrolytic relation is exponential - doubling for every 20°C (ref 02). Reducing a typical envelope temperature rise by 30% can increase lifetime by nearly an order of magnitude (ref 01). Failure rate and Mean Time Before Failure (80% characteristic survival) are generally improved.

In industrial applications either the temperature is controlled through the adoption of forced-air or liquid cooling, or special envelope materials and shapes are used. In audio circuits, where the noise of mechanically assisted cooling is generally a disincentive, and where suitable electron tubes are both limited in variety and increasingly expensive to source, cooling options are limited.

Thermally coupling the glass envelope to heatsinking is a difficult task, mostly due to:

a) rounded surfaces.

b) irregularity in dimensions.

c) mechanical fragility

of envelope materials.

d) differing coefficients

of thermal expansion existing between the envelopes and heat spreaders.

The thermal interface must be extremely flexible,

in order to do more good than harm.

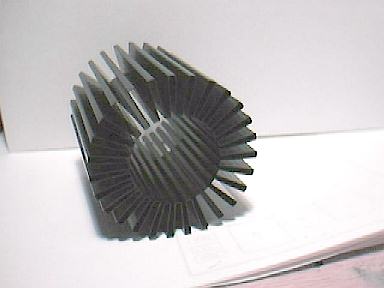

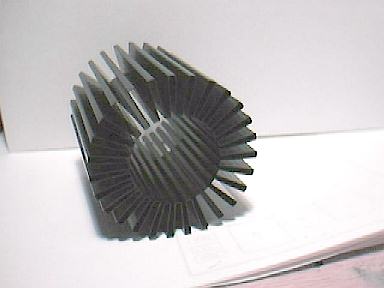

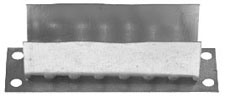

Thermal cuffs, constructed of optically absorptive and thermally conductive materials, act to increase the effective surface area of the envelope, reducing envelope thermal impedance to the surrounding ambient. Heat previously transferred by direct radiation, to detrimentally increase the temperature of surrounding components, is absorbed by the cuff and passed safely into the air, to be carried away by natural convection currents. This can improve the life of electrolytic and film capacitors in the immediate vicinity.

Due to the elasticity of the cuff's construction, a very low but even pressure can be maintained across the thermal interface which is largely unaffected by temperature, time or vibration. While stray capacity between the cuff and outermost elements of the tube internal structure are only a few picofarads, an electrically conductive cuff structure can also be used as an electrostatic screen to assist in the control of electromagnetic interference in noisy environments.

The technique was used in some commercial IERC tube

shield types, and also in early aerospace assemblies, where the cuff coupled

the envelope to metal tubes, which could in turn be heatsunk to a cooling

plate in low pressure or zeroG environments. http://www.ctscorp.com/ierc/

This cooling method is best suited for vacuum tubes with regular envelope shapes, such as those of the miniature, subminiature, or pencil silhouettes. In higher power types, the EL34, 6L6 and 6V6 are most suited, though cuffs can also be retrofitted to the structures of various transmitter tetrodes, CRTs, lasers, TWTs, and even Halogen tubes.

In order to be effective as a retrofit, conservative design practices must have been employed originally. A minimum spacing between vacuum tubes must be present, equal to the tubes' diameters, before cuffs can be fitted to adjacent devices. In those applications where forced air-cooling is already employed, a reduction in impeller power (and noise) is made possible.

The same hybrid construction principles can be used to develop lower-cost heat exchange elements in commercial HVAC systems. Tooling costs for this kind of bent aluminum sheet stock are quite low. If correctly dressed, the finished material is self-retaining.

Some commercial sources of prefabricated hardware are marketed by Pearl Audio. http://www.pearl-hifi.com/

IERC parts are still available as surplus.

http://www.surplussales.com/Tubes-Sock-Acc/TubeShields-1.html

REFERENCES:

1) M.W.Edwards, D.E.Lammers, J.A.Zoellner, “Subminiature Electron Tube Life Factors”, Engineering Publishers, Elizabeth, New Jersey, 1961. p156 .

2) Reimann, Arnold L., ”Vacuum Technique”, Chapman & Hall Ltd. London, 1952.p243-4.