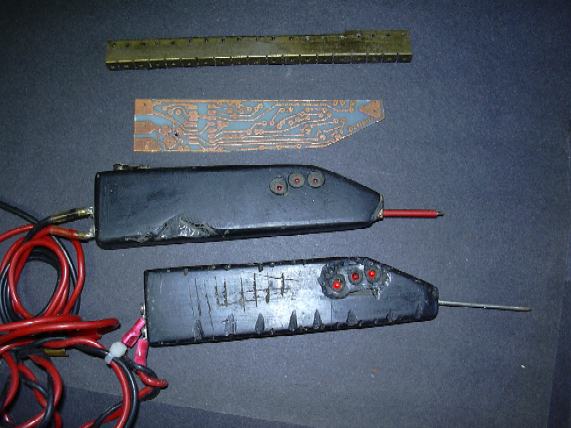

1982 - the Mauze - A simple logic probe designed to survive storage in a normal toolbox.

Probe tip and connections were made through tapped screw holes in brass, for ruggedness and repairability. Logic levels were adjusted by making or breaking a sliding blade terminal. Recessed indicators were present on both sides of the body - apertures were formed by disposable molded latex cups, introduced into the break-away re-usable polycarbonate molds.

The epoxy body cost twelve cents

per unit, plus labour. The tapped terminals and indicator cups were

used to position the board assembly within the mold. With a modest vacuum

applied, voids and air pockets could be avoided. The body was ground and

polished after break-out, to remove slick or sharp detail. The early prototypes

pictured here were pierced intentionally to search for air pockets.

Printed wiring was developed using photographic methods. An original letraset master pattern was transfered first to Kodak film, panelized for 10 units, then to KPR photoresist-sensitized .020 copper-clad boards.

Practically indestructible ........ unless dropped absolutely flat on it's broadest surface from a height of about 8 feet - when the epoxy would inevitably shatter in the location where indicators penetrated the epoxy. This flaw has been induced in one of the units shown, on about the fifth toss into the air, over a tiled concrete floor .......... when customers were watching, of course.

Indestructability is a hard claim to meet, after the fact, but these two development samples both still function normally, after rattling around in a toolbox with the wrenches and screw drivers, flaws and all, twenty-plus years later.

The schematic is unremarkable, using a standard 339 quad comparator and zener/supply references for amplitude comparison and 'pulse stretching' so that the indicators were visible. The simple technology of the application didn't last as long. They are still useful indicators for digital circuits operating from supplies as low as 3V, where no scope is handy.

A common question was;

" What does 'mauze' mean?".

As far as I know, it isn't an expletive in any language.